Design for Six Sigma (DFSS) for thermal assemblies :

- Define the Voice of the Customer (VOC): Gather customer inputs regarding thermal performance, noise levels, weight requirements, reliability expectations, and cost constraints. Translate these requirements into measurable metrics for each aspect.

- Identify Critical-to-Performance Characteristics: Determine the critical thermal performance parameters, such as temperature rise, heat dissipation efficiency, noise levels, weight targets, reliability metrics, and cost factors. These parameters significantly impact customer satisfaction and product success.

- Establish Design Objectives: Set specific design objectives for each critical characteristic, considering thermal performance, noise levels, weight optimization, reliability improvement, and cost reduction. Define target values or acceptable ranges for each parameter based on customer expectations and industry standards.

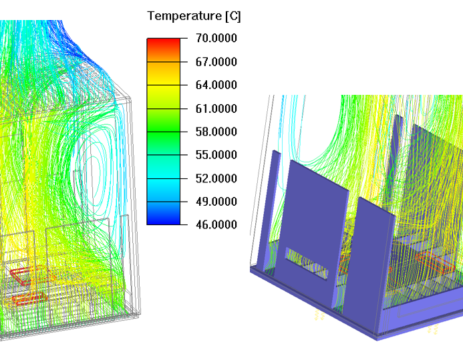

- Design Optimization and Simulation: Utilize advanced thermal modeling and simulation tools to optimize the TLA design. Perform simulations to assess and refine thermal performance, noise levels, weight distribution, and reliability aspects. Analyze the trade-offs between different design options to find the optimal balance.

- Robust Design and Parameter Optimization: Employ robust design techniques, such as Design of Experiments (DOE) and parameter optimization, to identify and control the key factors influencing thermal performance, noise, weight, reliability, and cost. Determine the optimal design settings that minimize variations and meet the defined objectives.

- Design Verification and Validation: Build prototypes and conduct testing to validate the thermal performance, noise levels, weight targets, reliability, and cost estimates. Ensure the TLA meets or exceeds the design objectives and fulfills customer requirements. Iterate the design as needed based on validation results.

- Design for Manufacturability (DFM) Considerations: Integrate DFM principles to ensure the thermal TLA design is manufacturable, cost-effective, and meets the desired performance, noise, weight, reliability, and cost goals. Consider material selection, component placement, manufacturing processes, and assembly techniques that optimize these aspects while maintaining thermal efficiency.

- Statistical Process Control (SPC): Implement SPC techniques during the manufacturing process to monitor and control thermal performance, noise levels, weight variations, reliability factors, and cost aspects. Maintain consistent quality and identify any deviations or trends that require corrective actions.

- Continuous Improvement: Embrace a culture of continuous improvement by collecting feedback from manufacturing, field performance, customer satisfaction surveys, and cost analyses. Use this feedback to drive further design refinements, optimize thermal performance, reduce noise levels, minimize weight, enhance reliability, and achieve cost efficiencies.

By incorporating these DFSS principles, manufacturers can develop thermal TLAs that excel in thermal performance, noise reduction, weight optimization, reliability enhancement, and cost-effectiveness. This approach ensures the products meet or exceed customer expectations and stand out in the market.

Latest Post

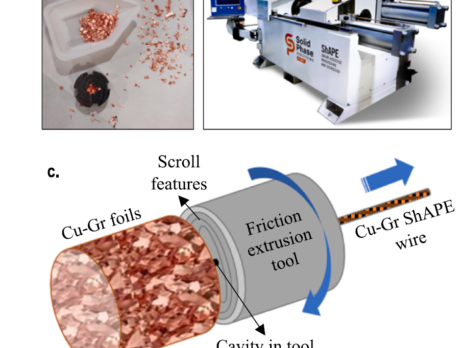

ShAPE-ing the Future: A New Technique for High-Performance Copper Composites

admin2024-01-15T11:11:21+00:00...

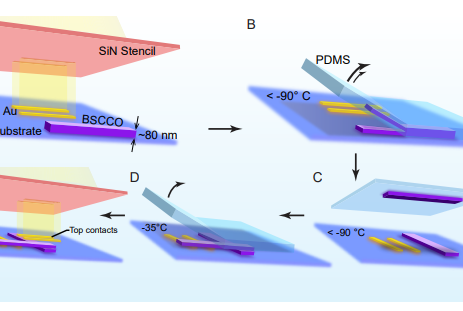

A High-Temperature Twist: Scientists Build the Foundation for Superconducting Switches of the Future

admin2023-12-20T09:15:01+00:00...

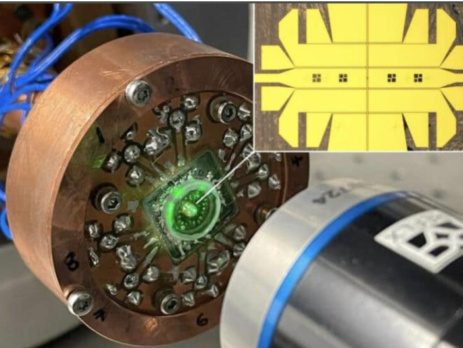

Room-Temperature Superconductivity: A Dream Inch Closer to Reality

admin2023-12-04T11:18:23+00:00...

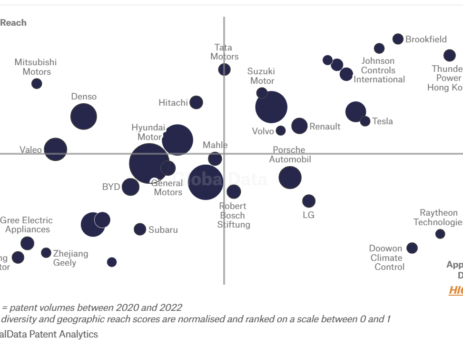

EV Thermal Management: Unveiling the Companies Shaping the Future of EV Cooling

admin2023-11-28T16:25:09+00:00...

Contact us

- Address: 7091 Kindra Hill Dr., San Jose, CA 95120

- Phone: +1 (408) 641-1398

- Email:sales@expertthermal.com